FOOD SAFETY IN CERAMC GLAZES

Understanding Food Safety in Ceramic Glazes: A Practical Perspective

Food safety in ceramics is a nuanced topic that begins with the glaze’s chemical formulation but can only truly be determined after firing. Factors like the silica-to-alumina ratio, oxide limits, and the presence of coloring or toxic metal oxides (e.g., lead, cadmium, barium) play a significant role in a glaze's potential safety even before firing. However, the final safety of the glaze depends on whether the firing process allows a complete chemical reaction to occur, forming a stable, inert glass surface.

This transformation during firing is not something that can be visually assessed, especially for matte or complex glazes. It relies on the intricate inner workings of glaze chemistry, ensuring the glaze fully melts and bonds with the ceramic body, leaving no reactive components behind. When this process is incomplete, harmful elements may leach into food or drink.

Key Considerations for Food Safety

Chemical Formulation

A well-designed glaze falls within specific chemical parameters (oxide limits) that ensure stability and inertness when fired correctly.

High levels of certain metal oxides (e.g., copper, manganese, cobalt) or toxic substances can pose safety risks if not carefully balanced within the glaze.

Proper Firing

Firing is crucial to completing the glaze’s chemical reaction. The temperature and duration must ensure that the glaze fully vitrifies (melts into glass).

If the glaze is underfired (not fully melted), it may remain porous, leachable, or chemically unstable, regardless of its pre-fired formulation.

Leaching and Stability

Properly fired glazes form an inert glass that resists interaction with food and drink, even under extreme conditions (e.g., high heat, acidity).

Improperly fired or unstable glazes, however, can leach metals or other elements, particularly when exposed to hot or acidic liquids.

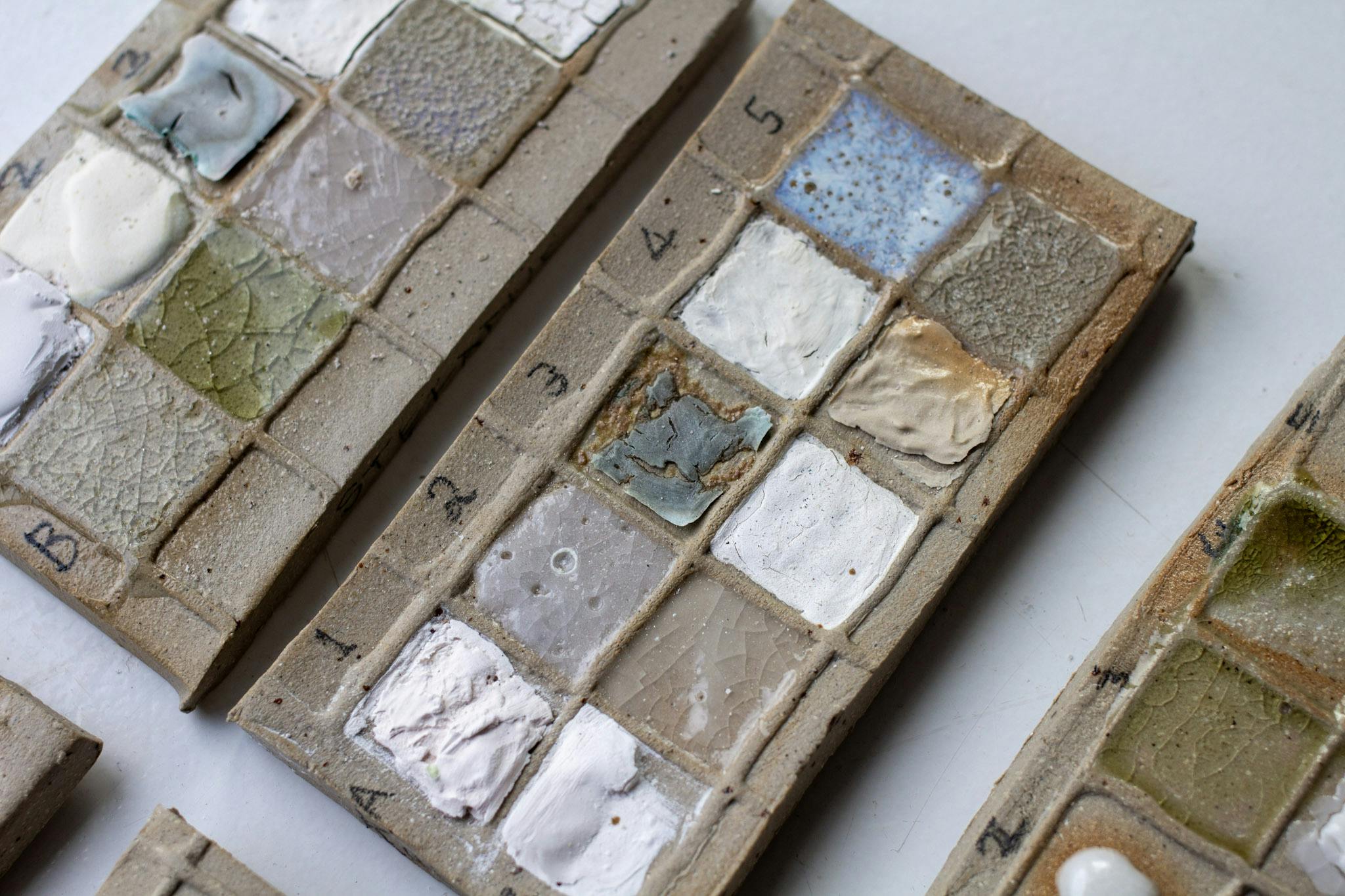

Surface Texture and Food Safety

Food safety isn’t just about a glaze’s chemical composition—it also depends on the texture of the finished glaze after firing. Textured or sculptural glazes with surfaces that blister, crawl, pit, or otherwise create uneven textures are unsuitable for areas that come into contact with food.

These surfaces can harbor bacteria in crevices, making them nearly impossible to clean thoroughly. While these finishes may offer visual or sculptural interest, they pose a health risk when used on functional ware. For food-safe ceramics, it’s essential to use smooth, sealed glazes on all surfaces intended for contact with food or drink.

Using a Liner Glaze for Added Safety

One of the simplest and most effective ways to ensure food safety is by using a liner glaze on the interior surfaces of ceramic ware—specifically the areas that come into contact with food or the mouth. A liner glaze is typically a stable, well-tested base glaze, often neutral in appearance (such as white or translucent), and formulated to minimize risks of leaching or instability.

In many cases, a liner glaze may rely on stains rather than coloring metal oxides to achieve its hue, as stains tend to be less reactive and more predictable in their behavior during firing. Alternatively, it may be applied over a slip or underglaze, creating a protective barrier while still allowing for decorative elements. By focusing on a liner glaze for functional surfaces, potters can significantly reduce the risk of harmful interactions while maintaining the visual appeal of their work.

Why Food Safety Cannot Be Certain Pre-Firing

While a glaze's chemical makeup provides clues about its potential safety, its ultimate behavior depends on how it is applied and fired. For instance:

Matte Glazes: These often have complex finishes, such as surface crystals or textures, which make it harder to assess if they’ve reached proper maturity during firing.

Brightly Colored Glazes: Glazes with high concentrations of coloring oxides can appear stable but require thorough testing to ensure no harmful leaching occurs.

Incomplete Firing: Even the best-formulated glaze can become unsafe if firing conditions are inconsistent or insufficient.

How to Ensure Food Safety

Test the Finished Ware: Post-firing testing is the only way to confirm a glaze’s stability and safety. This includes leaching tests with acidic liquids and thermal stress evaluations.

Use Safe Formulations: Stick to stable oxide combinations and avoid excessive use of metals or other reactive ingredients.

Fire Consistently: Achieving the correct temperature and soaking time during firing ensures that glazes fully vitrify into an inert, food-safe surface.

Avoid Textured Glazes for Food Surfaces: Use smooth, glossy, or satin glazes for any functional surfaces that will come into contact with food or drink.

Final Thoughts

Food safety in ceramic glazes involves both science and practice. While the glaze formulation sets the foundation, firing completes the process. A fully fired, inert glaze is safe for use, but this cannot be determined based on its ingredients or appearance alone. Additionally, incorporating a liner glaze for functional surfaces and avoiding textured glazes on food-contact areas are practical measures to further enhance safety. For potters, manufacturers, and consumers, awareness, proper testing, and informed choices are essential to ensuring ceramics are not only visually compelling but also safe for everyday use.